The Garment Development Process

- Supriya Ghurye

- Jan 20, 2022

- 2 min read

In the previous post while we took you inside the design room and tranquil of thoughts from forecast to mood-setting to conceptualization of a range. Now we take a trip to the product development department and sampling room of vendors where the range is given final shape before it moves to bulk production.

Product Development: Once the products are selected for the range, pattern generation and product development are eked out in several stages.

First in line is proto sampling in which prototypes are developed and required modifications are incorporated in terms of styling, fabric, trims. Sample garments are developed by apparel manufacturing vendors in sync with development sheets or preliminary tech packs offered by the buyers. Buying here refers to the team which is getting the range developed and co-coordinating with the vendors for its brand for the forthcoming season. Henceforth the vendor who manages to develop samples at the most optimum cost and stipulated time frame, thereby meeting all the prerequisites of technical specifications and aesthetics is given the final order.

Step by

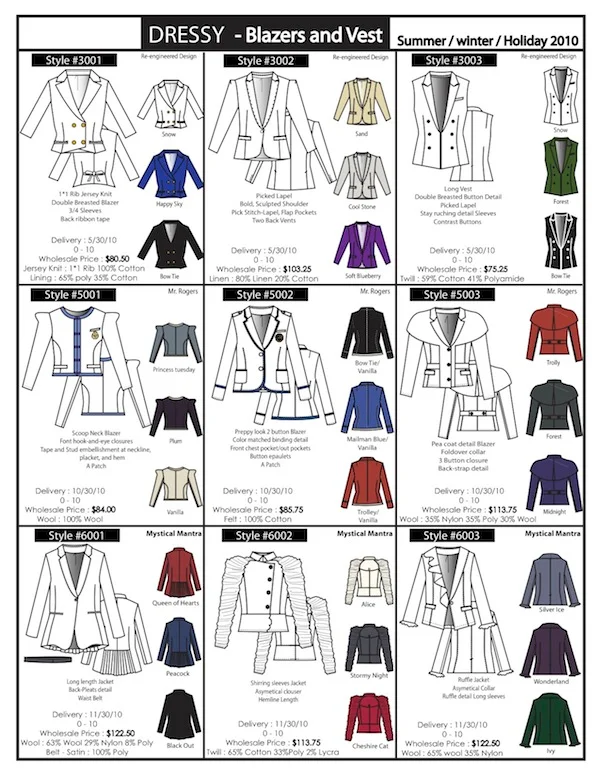

Post a rigorous process of cost negotiations and order placements, final tech packs are designed with crisp information on fabric construction, its properties(GSM, CPI/WPI), fabric body color, trim details with their positioning, measurement specifications, size chart, illustrations with a clear demarcation of each part and point of measurement. This tech pack is developed by the product development team in close collaboration with the design team. This is handed over to the buying team that posts it to the selected vendor.

The vendor refers to the tech pack and develops a fit sample taking stringent note of the measurements. It is sent across to the product development team who cross-checks all the technical specifications and provide required comments in case of discrepancies. Also, the measurements are re-evaluated and modified if required and sent across to the vendor for redevelopment. This process continues till a perfect sample meeting all the prerequisites is given a full form. Final patterns used for fit samples are replicated in soft copy and hard copy.

This maps out a route for bulk production with a prior submission of pre-production samples for validating the bulk fabric, trims being employed.

While sampling activities proceed on the order confirmation, on one hand, there are a series of activities that go simultaneously to enable smooth bulk production. Revisit our blog post to know all that goes on till the final garment is crafted and made available at your nearest retail outlet.

To engage our unique design skills, branding, marketing and consulting services to build your fashion brand, contact us

Don’t forget to sign-up for our newsletter to gain valuable insights into the inner workings of the fashion world.

Fuel4Fashion is a design, branding and business consultancy for the fashion and apparel industry. We provide consulting and advisory services across planning, design and business processes to early stage and mid-sized apparel manufacturers and brands looking to grow their business with the help of smart sustainable management practices. Visit our website here and follow us on Instagram and LinkedIn for regular updates.

Comments